EWAC R&D Centre was inaugurated in the year 1980 by Dr. Rene Wasserman, a pioneer in the field of low heat input 'Eutectic' welding products for Maintenance and Repair Applications across all types of industries. The vision of EWAC R&D Centre is to address customer specific needs and provide cost economic solutions for reclamation of industrial components. Over the last 4 decades, this research centre has assimilated high level of technological excellence and assisted Indian industries in improving industrial output by reducing down-time of machineries by adopting advanced maintenance and repair welding processes and alloy systems.

EWAC R&D Centre is recognised by "Department of Science & Industrial Research [DSIR], Govt. of India" since 1982. The core strength this R&D Centre is its team of well qualified and experienced researchers and specialists who focus on product, process and application developments in the areas of basic metallurgy, welding technology, coating solutions, brazing, soldering and polymer technologies in addition to failure analysis studies. This centre has state-of-the-art facilities to produce a steady stream of new, innovative and value engineered products. Some of the in-house facilities are as highlighted below :

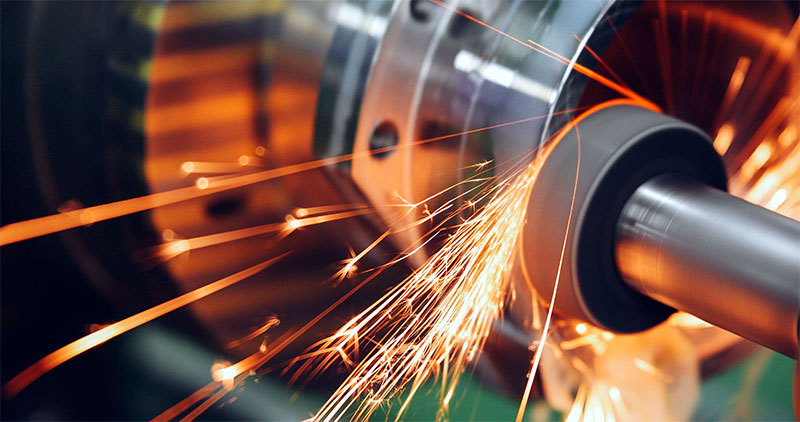

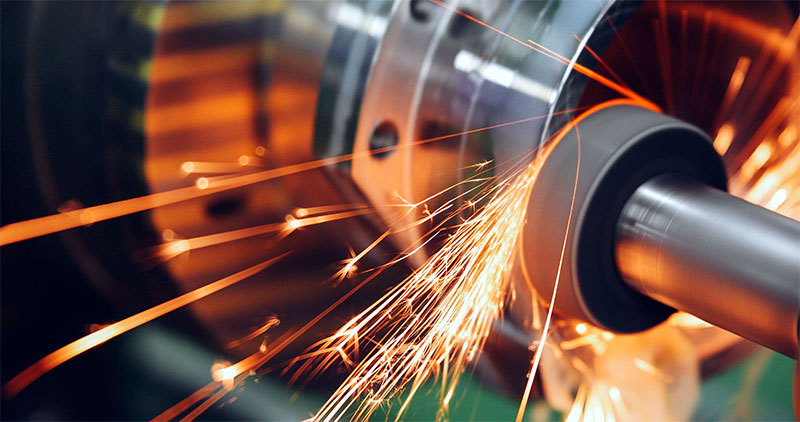

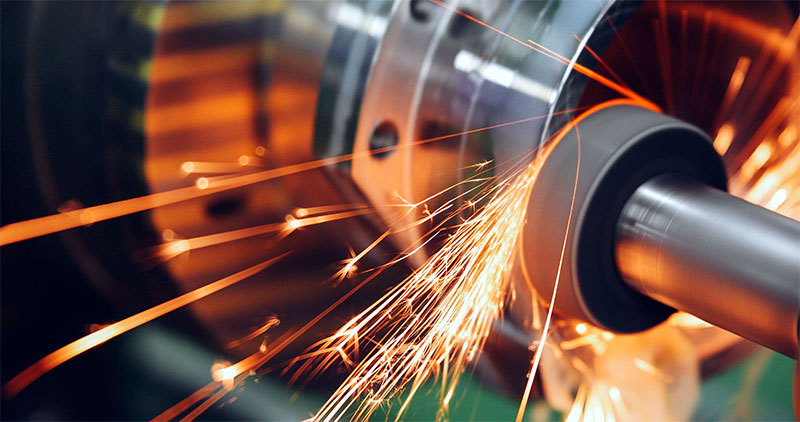

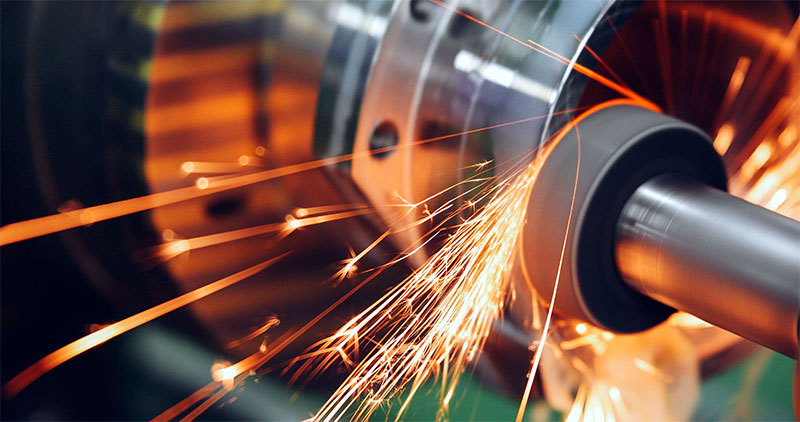

Exclusive test rigs have been developed to simulate service conditions for ranking product performance both at room temperature and at elevated temperatures. Some of the key equipments include:

Fast and accurate chemical analysis is a key factor for product development. This R&D Centre is equipped with modern equipments like Optical Emission Spectrometer, Positive metal identification and C, S, O2 & N2 Analysers.

The microstructural analysis enables R&D engineers to design products with desired microstructures, understand the failure mechanism and establish structure-property correlation. The latest opto-digital image analysis system with software for image acquisition, analysis and archiving with a large number of available functions sets new standards for scientific image processing.

EWAC R&D is equipped with pilot plants for coated electrodes, wear plates, steel mill reconditioning trials and polymer compounds. These are being extensively used during development to achieve perfection in the product before technology is transferred to the main production line.