EWAC, an expert in wear solutions, offers a range of Ceramic products that fight against heavy wear factors like Impact, Abrasion, Erosion etc. Our Ceramic range of products have an optimum density of 3.5 gm/cc, with high hardness (75 on R 45 N) to protect your valuable components.

Pastable and Weldable ceramic tiles with 90 - 92% Alumina content.

Thicker CERA GLIDE, can be welded with a metal ferrule on mother plate and a ceramic cap can be pasted above the welded ferrule to have a smooth surface.

Thinner CERA GLIDE, can be directly pasted on the mother plate / surface with the help of Epoxy resins suitable for substrate.

| Sr. No. | Product details (High Alumina Wear Resistant Ceramic Tiles) |

| 1 | 6mm thick with 50mm L X 50mm W (Pastable) |

| 2 | 8mm thick with 50mm L X 50mm W (Pastable) |

| 3 | 10mm thick with 100mm L X 100mm W (Pastable & Weldable) |

| 4 | 12mm thick with 100mm L X 100mm W (Pastable & Weldable) |

| 5 | 15mm thick with 100mm L X 50mm W (Weldable) |

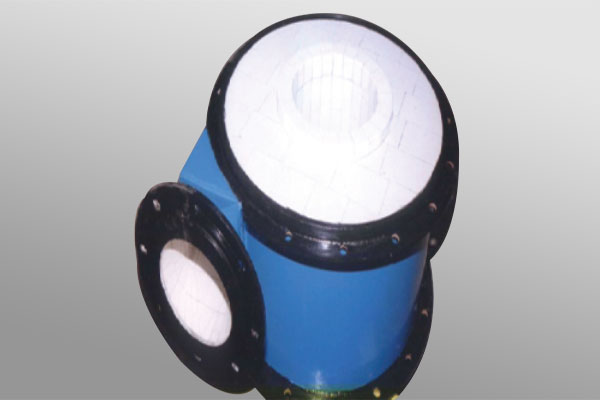

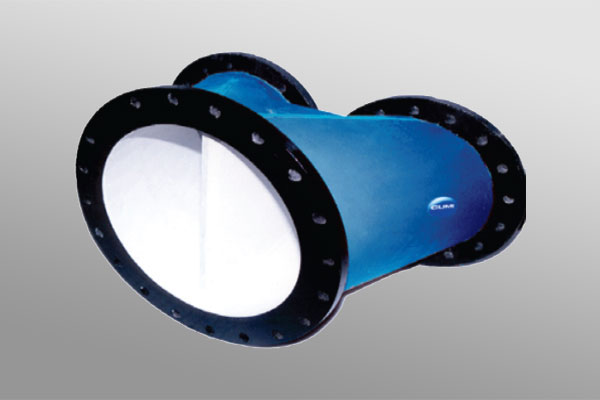

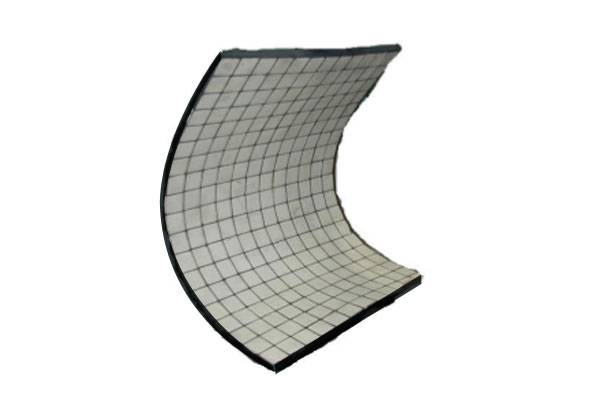

For non-standard profiles, EWAC can supply Pre-Engineered CERA GLIDE CLC tiles suiting to complex geometric profiles. Our expertise in CAD design ensures exact fit on the contours of any component and enhances its life, protecting from wear factors. EWAC can also supply Ceramic Lined Components of various shapes and sizes lined with Pre-Engineered tiles.

Customized range is available.

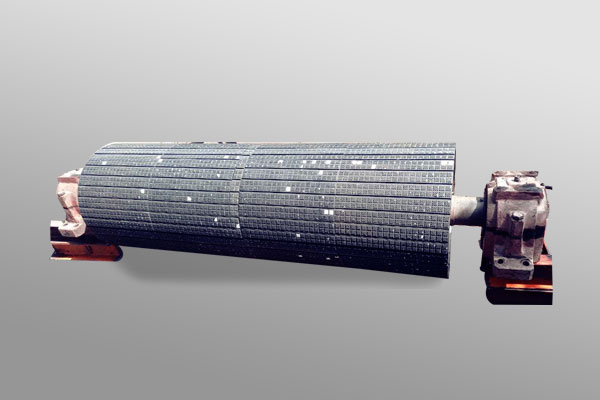

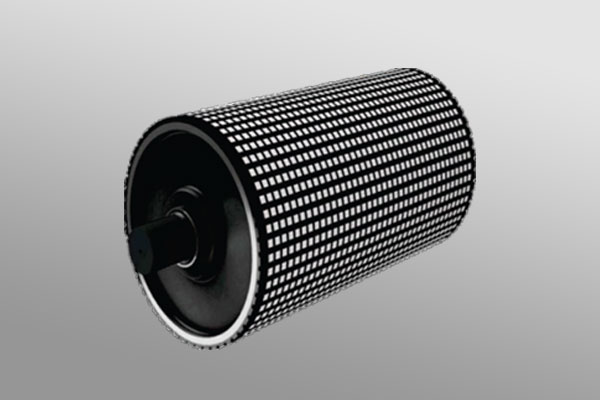

EWAC's ZUPERMAT PLC is ideal for Pully Lagging with a combination of alumina ceramic tiles & high-grade rubber, which increases the co-efficient of friction to reduce belt slippage even under wet or muddy conditions. The tiles are dimpled for positive contact with the conveyor belt.

| Pully Lagging Ceramic | Size |

| EWAC ZUPERMAT PLC | 500 X 500 X 12mm |

| 500 X 400 X 12mm | |

| 500 X 500 X 15mm | |

| 500 X 400 X 15mm | |

| 300 X 15mm Roll | |

| 300 X 12mm Roll |

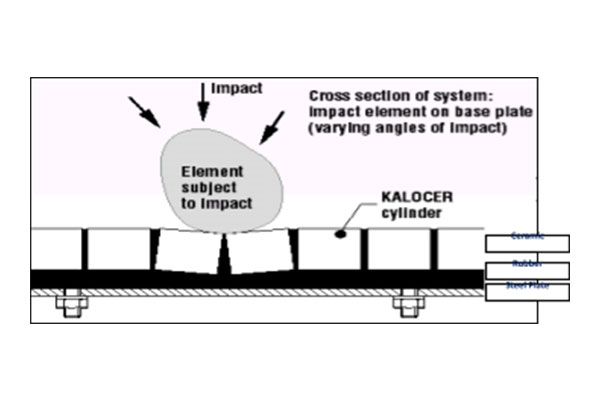

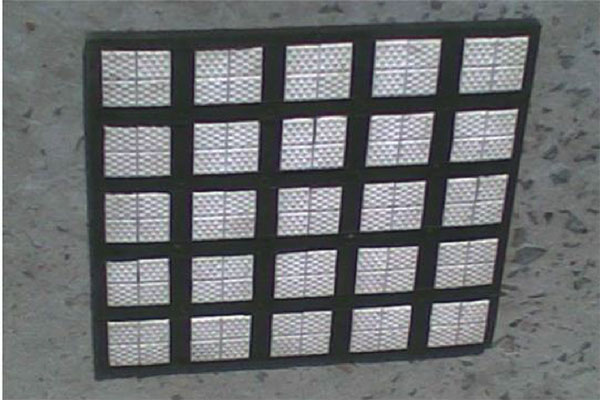

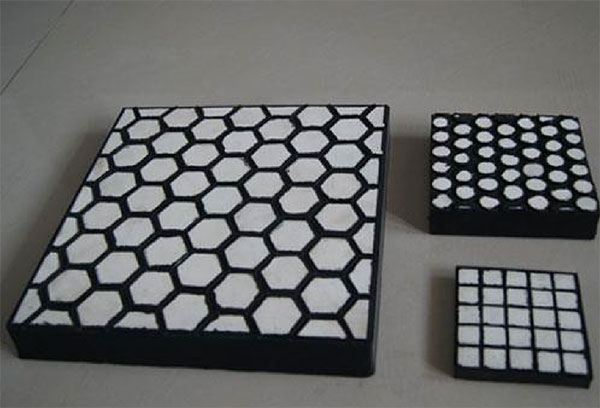

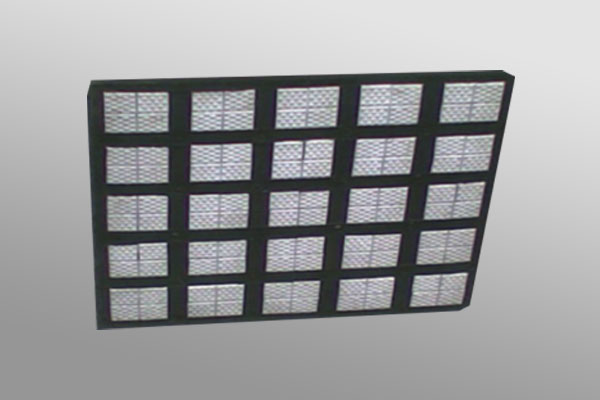

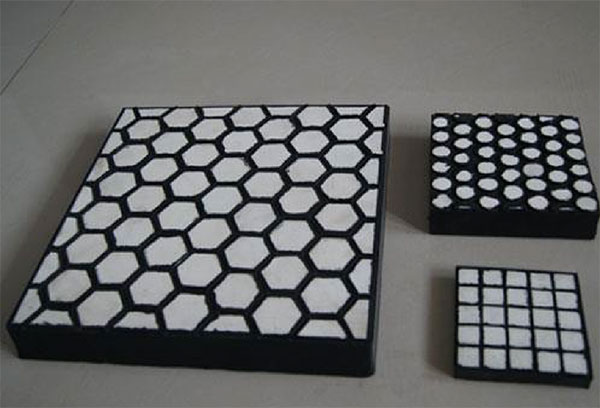

This liner is a combination of high-quality alumina ceramic tiles embedded in special rubber and is suitable for applications where material is falling from a height. Main advantage is that the ceramic tiles can resist abrasion and the rubber can take high impact load. These RBC liners can be directly pasted on the mother plate using Epoxy Resin.

Available sizes:

| Sr. No. | Tile Size | MAT size | The thickness is variable according to tile requirement |

| 1. | 150 X 100 X 15mm | 520 X 630 X 20mm | Available in 10, 12, 15, 20, 25mm thickness with Rubber thickness of 5, 7, 10, 12, 15, 20mm. |

| 2. | 50 X 50 X 10mm | 500 X 500 X 20mm | Available in 6, 8, 10, 12, 15, 20mm thickness with Rubber thickness of 5, 7, 10, 12, 15, 20mm. |

| 3. | 25 X 25 X 6mm | 500 X 500 X 8mm | Available in 6, 8, 10mm thickness with Rubber thickness of 5, 7, 10mm. |

| 4. | 20 X 20 X 8mm Hexagonal | 500 X 500 X 13mm | Available in 6, 8, 10, 15mm thickness with Rubber thickness of 10, 15, 20mm. |

| 5. | 25 X 25 X 10mm Hexagonal | 500 X 500 X 15mm | Available in 10, 12, 15,20mm thickness with Rubber thickness of 5mm, 10mm, 15mm, 20mm. |

| 6. | 20 X 20 X 10mm Cylindrical | 500 X 500 X 15mm | Available in 10, 15, 20,25mm thickness with Rubber thickness of 5, 10, 15, 20mm. |

These liners are same as EWAC ZUPERMAT RBC but additionally backed by 3mm or 5mm MS Plate with Studs. These RMS Liners can be directly bolted on the mother plate.